Pop-up canopies and tents are part of daily life in the United States. Families use them for backyard parties, athletes rely on them for sporting events, and businesses depend on them at trade shows and outdoor festivals. They provide shade, shelter, and space in minutes.

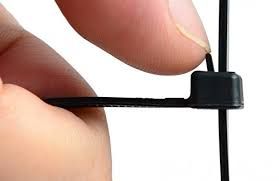

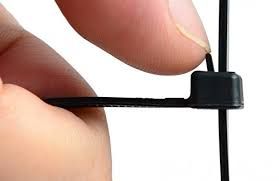

The one challenge is securing them. Standard ties can keep fabric and poles in place, but they are single-use and slow to adjust. That is where quick-release cable ties make a difference. Built for speed and flexibility, they allow users to fasten and unfasten structures quickly without cutting.

This guide explains why quick-release ties are ideal for canopies and tents, how to use them, and which products offer the best performance.

Why Pop-Up Structures Need Quick-Release Solutions

Pop-up canopies and tents must handle frequent setup and breakdown. Whether for tailgating, outdoor markets, or emergency shelters, time is valuable. Traditional nylon ties, once tightened, need cutting tools to remove. This slows down the process and creates waste.

Quick-release ties solve the problem by combining strength with reusability. With a built-in release mechanism, they are tightened like traditional ties but can be undone instantly with a tab or lever. This feature saves time and keeps ties reusable.

Benefits of Quick-Release Cable Ties

Speed

Setup and takedown become faster. Instead of reaching for cutters, users release ties in seconds.

Reusability

Unlike single-use ties, quick-release versions last through multiple events. This saves money and reduces waste.

Flexibility

Canopies and tents often need adjustments for fabric tension or pole stability. Quick-release ties allow fine-tuning without sacrificing strength.

Safety

By eliminating the need for cutters, quick-release ties reduce injury risks. No sharp tools are required during breakdown.

Common Uses in Canopies and Tents

- Securing poles: Attach poles to each other or to fences for stability.

- Fastening fabric: Keep covers tight against wind and movement.

- Holding accessories: Attach lights, banners, or decorations safely.

- Bundling gear: Organize ropes, cords, and tools during transport.

Their versatility makes quick-release ties a must-have for anyone working with portable shelters.

Material Options for Outdoor Use

Quick-release ties come in different materials to match environments.

Standard Nylon

Lightweight and affordable, nylon quick-release ties work well for occasional use in mild weather.

UV-Resistant Nylon

For outdoor events in sun and rain, UV-resistant nylon prevents cracking and fading, ensuring ties last longer.

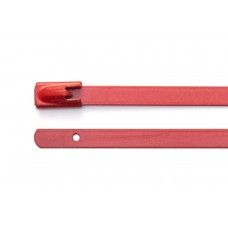

Stainless Steel

For heavy-duty shelters exposed to extreme wind or salt air, coated stainless steel quick-release ties provide unmatched strength and durability.

Preventing Common Problems

Over-tightening

Quick-release ties are reusable, but over-tightening reduces lifespan. Use only the tension needed.

Choosing wrong size

Small ties may not secure thick poles or fabric. Always match tie length and tensile strength to the task.

Exposure to extremes

Select UV-resistant or stainless steel versions when storing or using tents outdoors for extended periods.

Industry Applications

Outdoor Events

Event planners rely on canopies for booths, food stalls, and stages. Quick-release ties simplify repeated setups across venues.

Sports Teams

Athletes and teams use pop-up shelters for sideline shade. Quick-release ties allow rapid adjustments when moving between fields.

Emergency Response

First responders deploy tents as medical or command stations. Quick-release ties provide fast, secure assembly in urgent scenarios.

Camping and Recreation

Campers and hikers appreciate ties for securing gear, hanging tarps, and adjusting tents with minimal hassle.

Trade Shows

Exhibitors use ties to secure banners, signage, and lighting to booths. Quick-release designs make daily setup and teardown efficient.

Tips for Effective Use

- Keep multiple sizes of ties in kits for different canopy parts.

- Store ties in a dry, cool location to maintain strength.

- Practice release mechanisms before use to avoid delays at events.

- Combine ties with stakes or weights for maximum stability in wind.

Cost Versus Value

Quick-release ties cost more upfront than single-use versions. However, their reusability quickly offsets the cost. By lasting through multiple events, they reduce waste and improve efficiency. For frequent canopy or tent users, they represent strong long-term value.

Product Review: Releasable Cable Ties

Cable Ties Unlimited offers Releasable Cable Ties that excel in canopy and tent applications. Built from durable nylon 6/6, they feature a release tab for instant removal.

Available in multiple lengths and tensile strengths, these ties handle both small adjustments and large structures. Their design allows reuse, making them ideal for events, camping, and emergency deployments.

For U.S. customers looking for versatile outdoor solutions, releasable ties provide durability, speed, and efficiency. They outperform single-use options by supporting both security and convenience.

Mistakes to Avoid

- Using indoor ties outdoors: Non-UV ties crack quickly in sunlight.

- Failing to reuse properly: Reusable ties must be released gently to preserve strength.

- Skipping backups: Always carry extra ties for unexpected needs.

- Ignoring tension tools: Large structures may require tension tools for consistency.

Future of Quick-Release Ties

As demand for sustainable and reusable solutions grows, manufacturers are innovating new quick-release mechanisms. Expect to see ties with smoother locking systems, ergonomic release tabs, and eco-friendly materials.

Custom branding may also emerge, allowing businesses to use ties that match event branding while providing functionality.

Wrapping Up

Quick-release ties transform how people secure pop-up canopies and tents. Their speed, reusability, and safety advantages make them superior to standard ties. Whether for families, businesses, or emergency responders, they provide efficiency and reliability outdoors.

Products like Releasable Cable Ties from Cable Ties Unlimited highlight the value of reusable, durable solutions. Designed for quick adjustments, they make setup and breakdown seamless.

For U.S. customers seeking dependable event and outdoor solutions, quick-release ties are a small investment with significant returns.

For more insights and tips on cable ties and other related products, explore cabletiesunlimited.com, get a quick and free quote, and follow us on our social media communities on Facebook and Instagram!

Quick-release cable ties make pop-up canopies and tents faster to secure and easier to adjust. Learn how these reusable ties deliver strength and efficiency outdoors.

Emergency kits exist to save time when every second counts. They provide tools, supplies, and equipment needed for unpredictable situations. From natural disasters to roadside breakdowns, these kits are built around versatility and preparedness. One of the most overlooked but essential items is the cable tie.

Cable ties are simple, inexpensive, and compact, yet their value in emergencies is unmatched. They secure, fasten, repair, and organize under pressure. Whether in a glove box kit, workplace first aid cabinet, or disaster preparedness bag, cable ties belong alongside flashlights and batteries.

This guide explores how cable ties support emergency readiness, which types are best, and how to store them effectively.

Why Cable Ties Belong in Emergency Kits

Cable ties are lightweight and take up almost no space. Yet their tensile strength allows them to perform heavy-duty tasks. In unpredictable scenarios, their adaptability makes them indispensable.

Key reasons they fit in emergency kits include:

- Multi-purpose use: From first aid to temporary repairs, they adapt instantly.

- Compact storage: A handful of ties fits into any kit without bulk.

- Low cost: Adding them to kits requires minimal investment.

- Reliability: Ties work under heat, cold, or stress with no moving parts to fail.

When emergencies arise, versatility matters more than anything else. Cable ties provide exactly that.

Practical Uses in Emergency Situations

Securing Gear

In roadside emergencies, loose items become hazards. Cable ties secure tools, flashlights, or gear to prevent movement.

Temporary Repairs

Broken straps, buckles, or zippers can be replaced temporarily with cable ties. They hold gear together until proper repairs are possible.

First Aid Support

In first aid, cable ties can improvise splints by fastening sticks or boards to immobilize injuries. They can also secure bandages when tape is unavailable.

Shelter Building

For disaster scenarios, cable ties help assemble tarps, tie poles, and construct temporary shelters. Their strength and speed make them useful in harsh weather.

Automotive and Transport

When vehicles break down, cable ties secure loose hoses, cables, or body panels temporarily. They provide a quick fix to get moving again.

Organizing Supplies

Emergency kits often include cords, straps, and tools. Cable ties bundle these neatly, ensuring quick access when needed.

Choosing the Right Cable Ties for Emergency Kits

Not all cable ties perform equally. Emergency kits demand durability, versatility, and reliability across conditions.

Standard Nylon Ties

Affordable and versatile, standard nylon ties work well for general uses. They are best for indoor or short-term outdoor needs.

UV-Resistant Nylon Ties

For outdoor emergencies, UV-resistant ties withstand sun and weather longer. They are stronger than standard nylon and less prone to cracking.

Releasable Ties

Releasable designs allow reuse, ideal when supplies are limited. In emergency kits, this reduces waste and extends functionality.

Stainless Steel Ties

For extreme heat or rugged conditions, stainless steel ties offer unmatched durability. They hold up against fire, vibration, and corrosion.

Hook-and-Loop Straps

While not true cable ties, hook-and-loop straps complement kits with adjustable, reusable fastening options.

How Many Ties Should Be in a Kit?

The number of ties depends on the kit’s purpose.

- Glove box kits: 10 to 20 assorted nylon ties.

- Disaster kits: 30 to 50 ties in multiple sizes and materials.

- Workplace kits: Larger assortments, including stainless steel or releasable versions.

Carrying ties in various sizes ensures readiness for small and large tasks alike.

Storing Cable Ties in Kits

Cable ties must remain in good condition until needed.

- Keep them dry: Store in sealed bags to prevent moisture damage.

- Avoid heat: Prolonged exposure to high temperatures weakens nylon ties.

- Organize by size: Separate small, medium, and large ties for quick selection.

- Combine materials: Include both nylon and stainless steel for versatility.

Organized storage ensures ties are ready at a moment’s notice.

Industry Applications

Outdoor Recreation

Hikers, campers, and climbers carry cable ties for gear repair and safety. They secure packs, fix tent poles, and replace broken straps in the field.

Emergency Responders

Firefighters and paramedics use cable ties for securing gear, organizing supplies, and quick fixes during operations.

Transportation

Truck drivers and pilots carry emergency kits with cable ties to secure loads or repair minor equipment issues.

Households

Home emergency kits benefit from ties for everything from fastening tarps after storms to quick appliance fixes.

Training Employees and Families

Having cable ties in emergency kits is not enough. People must know how to use them. Training sessions or simple instructions inside kits help employees, families, or team members use ties effectively.

Scenarios to practice include:

- Building a temporary shelter.

- Securing a splint.

- Repairing a broken strap or zipper.

- Fastening loose wires or cables.

Preparedness increases when everyone understands the power of a simple cable tie.

Product Review: Emergency Cable Tie Assortments

Cable Ties Unlimited offers Cable Tie Assortments that make ideal additions to emergency kits. Each assortment provides multiple sizes and strengths, ensuring readiness for different situations.

Made from durable nylon 6/6, these ties cover both light and heavy-duty applications. Options include natural, black UV-resistant, and colored ties, adding both versatility and organization.

Compact packaging makes them easy to store in glove boxes, backpacks, or workplace kits. For U.S. offices, households, and field workers, these assortments ensure the right tie is always on hand in emergencies.

Mistakes to Avoid

- Packing only one size: Small ties cannot handle large repairs, while oversized ties waste space.

- Ignoring weather resistance: Standard ties fail quickly in sun or rain.

- Over-relying on nylon: Include stainless steel or releasable versions for tougher conditions.

- Failing to train users: Tools are only useful when people know how to apply them.

The Cost of Being Unprepared

Without cable ties, small issues become big problems. A loose hose can disable a vehicle. A broken tent pole can leave campers exposed. In emergencies, time wasted improvising replacements can put lives at risk.

For minimal cost, cable ties add significant preparedness.

Future of Cable Ties in Preparedness

Manufacturers are developing advanced materials that improve strength and weather resistance. Recyclable and biodegradable options may soon add sustainability to emergency kits.

Smart cable ties could also emerge. These ties may include indicators that show tension or wear, helping users judge reliability in high-stress situations.

As emergency preparedness becomes more advanced, cable ties will remain a fundamental tool.

Wrapping Up

Emergency kits succeed when they provide versatile, reliable tools. Cable ties meet this standard with strength, adaptability, and simplicity. They secure gear, support first aid, and provide quick repairs in stressful situations.

Products like Emergency Cable Tie Assortments from Cable Ties Unlimited deliver the variety and reliability needed for U.S. offices, households, and field kits. With multiple sizes and types, they ensure preparedness across any emergency scenario.

For modern preparedness planning, cable ties are not optional. They are essential, compact tools that transform emergency kits from basic supplies into reliable life-saving resources.

For more insights and tips on cable ties and other related products, explore cabletiesunlimited.com, get a quick and free quote, and follow us on our social media communities on Facebook and Instagram!

Emergency cable ties secure gear, repair equipment, and support first aid. Learn why they belong in every emergency kit and which types perform best.

Cable ties are practical tools. They organize wires, bundle equipment, and keep spaces safe. Yet in modern office design, cable ties have taken on a second role: aesthetics. The colors chosen for cable ties can enhance organization while influencing the visual feel of a workspace.

In an age where office interiors reflect brand identity, design choices extend beyond furniture and paint. Even small details like cable ties matter. Color palettes used for cable ties can reinforce professionalism, support branding, and contribute to a cleaner, more modern atmosphere.

This guide explores how color palettes influence office aesthetics, why they matter, and how to integrate them effectively.

Why Color Matters in Offices

Color shapes perception. It influences mood, productivity, and the impression a company leaves on clients and employees. Offices invest heavily in décor, lighting, and branding. Overlooked details like cables and ties can disrupt the look of otherwise well-planned spaces.

A tangle of mismatched ties creates visual clutter. Carefully selected color palettes, on the other hand, align technology with design. Organized cable management becomes part of the office’s style rather than a distraction.

Cable Tie Color Options

Cable ties are available in a wide range of colors, from subtle neutrals to bold, vibrant hues. Each serves both functional and aesthetic purposes.

- Black: Professional, minimal, and widely used for hiding ties in office furniture.

- White/Natural: Blends with lighter décor, common in open and bright offices.

- Clear: Nearly invisible, offering discreet management for modern interiors.

- Bright colors: Red, blue, green, and yellow ties add energy or support color-coded systems.

- Custom colors: Some manufacturers provide ties in brand-specific shades.

The Role of Color Coding

While aesthetics are important, functionality cannot be ignored. Offices often use color coding to simplify cable management. For instance:

- Red ties: Power lines.

- Blue ties: Networking cables.

- Green ties: Grounding or environmental systems.

- Yellow ties: Temporary or caution-related wiring.

When carefully applied, this dual role enhances both appearance and organization.

Matching Cable Ties to Office Design

Neutral Palettes

Neutral tones like black, white, or clear ties integrate seamlessly into modern office environments. Black ties disappear against dark desks, while clear ties blend with glass or minimalist surfaces.

Bold Accents

In creative offices, bright ties double as accents. They provide pops of color that complement art, furniture, or branding. These small details add vibrancy without overwhelming the space.

Brand Identity

Custom-colored ties can match company colors. For tech firms or creative agencies, ties in signature hues reinforce brand identity. A detail as small as cable ties can carry branding into the workspace subtly but effectively.

Industry Examples

Corporate Headquarters

Large offices often choose black or white ties to maintain professionalism. Minimalist palettes align with formal business décor.

Creative Agencies

Design-driven firms embrace bright colors. Matching ties to accent walls or logos reinforces a playful, energetic atmosphere.

Tech Startups

Startups frequently mix functionality and style. Color-coded ties keep server rooms organized while offering bold visuals that highlight innovation.

Co-Working Spaces

Shared spaces benefit from clear or neutral ties that adapt to varying design styles without clashing.

Benefits of Aesthetic Cable Management

- Professionalism: Organized, well-matched cables leave a positive impression on visitors.

- Employee satisfaction: Clean, thoughtfully designed spaces improve workplace morale.

- Brand reinforcement: Color palettes remind employees and clients of identity and values.

- Functionality: Aesthetic choices align with color coding for efficiency.

Tools That Support Design

Aesthetic cable management works best with supporting tools.

- Adhesive mounts: Secure ties invisibly to furniture.

- Labeling systems: Add clarity alongside color coding.

- Releasable ties: Allow adjustments without cutting, preserving clean lines.

Combining these tools with aesthetic ties keeps workspaces polished and functional.

Product Review: Colored Cable Ties

Cable Ties Unlimited offers Colored Cable Ties in a variety of hues to fit modern office needs. From bold red and blue to more subtle tones, these ties provide both function and design flexibility.

Made from durable nylon 6/6, they deliver reliable tensile strength while adding visual appeal. They are available in multiple lengths, making them suitable for everything from desktop cable organization to larger wiring setups.

For offices aiming to merge aesthetics with functionality, these colored ties are a versatile solution. They allow for both professional appearance and practical color coding.

Mistakes to Avoid

- Overusing bright colors: Too many bold ties create visual clutter.

- Ignoring décor: Ties that clash with design reduce overall polish.

- Neglecting organization: Aesthetic choices must still prioritize function.

- Skipping quality: Low-quality colored ties fade quickly, ruining the effect.

Cost Versus Value

Colored cable ties cost slightly more than basic black or white ties. However, the added value in branding, aesthetics, and improved organization outweighs the expense. Offices that prioritize professional appearance benefit from these small investments.

Future of Office Cable Tie Design

Manufacturers are experimenting with sustainable dyes and recyclable materials. Future ties may combine eco-friendly production with vibrant, long-lasting colors.

Customization is also advancing. Offices may soon order ties in exact Pantone shades for brand consistency. Smart ties with embedded identifiers could add digital coding to visual design.

Wrapping Up

Cable ties are no longer hidden details. In modern offices, their colors shape aesthetics, reinforce branding, and support organization. Thoughtful selection of palettes creates cleaner, more professional, and more inspiring workplaces.

Products like Colored Cable Ties from Cable Ties Unlimited combine strength with style. Available in a variety of colors, they help offices balance aesthetics and function.

For U.S. companies that value both appearance and performance, investing in cable tie color palettes turns a simple tool into a design asset.

For more insights and tips on cable ties and other related products, explore cabletiesunlimited.com, get a quick and free quote, and follow us on our social media communities on Facebook and Instagram!

Colored cable ties add style and organization to offices. Learn how palettes support branding and modern aesthetics while keeping wiring neat.

Cable ties are everywhere in office environments. They bundle cables under desks, keep server rooms tidy, and organize wiring in meeting spaces. Over time, these ties break, stretch, or get replaced during upgrades. Most end up in the trash. That waste adds up quickly in modern offices.

Recycling stations dedicated to cable ties provide a smarter solution. By collecting old ties, offices reduce waste, improve sustainability, and even cut long-term costs. Recycling is no longer just for bottles and cans—it now extends to everyday tools like cable ties.

This guide explores why recycling cable ties matters, how offices can set up collection stations, and which products support sustainable practices.

Why Cable Tie Recycling Matters

Nylon 6/6, the most common material in cable ties, is strong, flexible, and widely used. However, it is not biodegradable. When tossed into the trash, nylon ties sit in landfills for decades.

In the United States alone, offices consume millions of cable ties each year. Small ties from cubicles, larger ties from data centers, and specialized ties for office equipment all contribute to waste streams. Without recycling, the environmental footprint grows.

Recycling cable ties closes the loop. Instead of wasting resources, nylon can be repurposed into new products. Offices gain credibility for sustainability efforts while reducing landfill contributions.

Benefits of Office Recycling Stations

Environmental Impact

Recycling reduces waste, keeps plastic out of landfills, and supports a circular economy. Offices can proudly claim measurable sustainability achievements.

Corporate Responsibility

Companies face increasing pressure to adopt eco-friendly practices. Cable tie recycling aligns with broader environmental commitments and corporate social responsibility goals.

Cost Savings

Recycling does not just reduce disposal costs. Many recycling programs offer incentives or reduced fees for collected plastics.

Employee Engagement

Visible recycling stations remind employees of sustainability goals. Participation creates a culture of responsibility, improving workplace morale.

How Recycling Stations Work

Setting up a station is simple and requires minimal resources.

- Collection bins: Place labeled containers in strategic spots like server rooms or supply closets.

- Education: Train employees on what can and cannot be recycled.

- Partnerships: Work with recycling providers that accept nylon 6/6.

- Monitoring: Assign a team to oversee collection and ensure bins are used properly.

- Reporting: Track quantities recycled to showcase achievements.

Offices that follow these steps build a sustainable and effective recycling program.

Challenges to Overcome

While recycling cable ties is possible, offices face a few hurdles.

- Contamination: Ties mixed with other waste may not be recyclable.

- Logistics: Coordinating pick-ups requires planning.

- Awareness: Employees must learn which materials qualify.

These challenges can be addressed with clear signage, regular reminders, and reliable recycling partners.

Alternatives to Single-Use Ties

Reducing waste starts with better product selection. Offices can minimize disposal by choosing reusable options.

Releasable Ties

Releasable cable ties can be unlocked and reused multiple times. They are perfect for offices where wiring changes frequently.

Hook-and-Loop Straps

Velcro-style straps offer easy reuse. They are gentle on cables and ideal for desks and office equipment.

Biodegradable Ties

Some newer cable ties are made with biodegradable materials. While not as strong as nylon, they work well in light-duty office applications.

Using these alternatives reduces how many ties need recycling in the first place.

Industry Examples

Technology Offices

Server-heavy workplaces generate huge volumes of old ties. Recycling keeps waste manageable and aligns with tech industry sustainability standards.

Corporate Headquarters

Large offices have constant IT upgrades and relocations. Recycling stations capture old ties that would otherwise be tossed during projects.

Education and Government

Universities and public offices face strict sustainability reporting requirements. Recycling cable ties supports compliance and demonstrates leadership.

Tools That Support Recycling

Setting up a station is easier with the right tools.

- Clear signage: Labels showing accepted items reduce contamination.

- Reusable alternatives: Offering employees releasable ties helps cut waste.

- Tracking systems: Simple logs or apps document collection volumes.

These tools strengthen office recycling initiatives.

Product Review: Releasable Cable Ties

Cable Ties Unlimited provides Releasable Cable Ties that support sustainable office practices. Unlike standard nylon ties, these can be unlocked and reused multiple times. Their release tab makes adjustments quick and easy without cutting or discarding ties.

Made from durable nylon 6/6, they maintain strong tensile strength while reducing single-use waste. Available in multiple lengths and tensile ratings, they work for everything from desk setups to server rooms.

For offices that want to reduce waste before recycling, releasable cable ties offer a practical and eco-friendly alternative.

Mistakes to Avoid

- Mixing waste: Recycling stations should accept only cable ties, not general plastic waste.

- Ignoring training: Employees must understand the system for it to succeed.

- Overlooking alternatives: Relying only on recycling instead of reducing use limits impact.

- Failing to track progress: Without data, offices cannot show results.

The Cost of Ignoring Recycling

Offices that skip recycling miss opportunities for savings and sustainability. Landfill disposal costs money and creates negative environmental impact. Employees also notice when companies neglect responsibility. A lack of visible action reduces morale and damages brand image.

Future of Cable Tie Recycling

The future points toward closed-loop systems. Manufacturers are experimenting with take-back programs, where used ties are returned and processed into new products. Offices may one day ship old ties back directly to suppliers.

Biodegradable alternatives are also improving. As materials strengthen, compostable ties could replace nylon for light office use, eliminating the recycling challenge entirely.

Digital reporting tools will make tracking easier. Offices may soon measure exactly how many pounds of cable ties are recycled each year, adding transparency to sustainability reports.

Wrapping Up

Cable ties are essential in modern offices, but their disposal cannot be ignored. Recycling stations provide a simple, effective way to reduce waste, save money, and engage employees. Combined with reusable alternatives, they transform cable management into a sustainable practice.

Products like Releasable Cable Ties from Cable Ties Unlimited reduce waste at the source, making office recycling programs even more effective.

For U.S. offices striving for greener operations, cable tie recycling is a small step with a big impact. With the right stations, training, and products, every office can turn waste into sustainability.

For more insights and tips on cable ties and other related products, explore cabletiesunlimited.com, get a quick and free quote, and follow us on our social media communities on Facebook and Instagram!

Offices use thousands of cable ties each year. Learn how recycling stations reduce waste and why releasable cable ties help make offices more sustainable.

Cable ties are built to secure and organize. They hold cables in bundles, fasten wiring to structures, and provide stability. Over time, however, cable ties can stretch. This slow change reduces tension, loosens bundles, and risks failure in demanding environments.

Stretching may not be immediately obvious. A tie that seems tight today might sag in months or years. In outdoor or high-stress settings, stretched ties create major problems. Understanding why ties stretch and how to prevent it saves money, time, and safety hazards.

This guide explores the causes of cable tie stretch, its impact on projects, and prevention strategies for long-term reliability.

Why Cable Ties Stretch

Cable ties are typically made of nylon. While strong and flexible, nylon is subject to stress relaxation. This means tension decreases over time, especially under constant load.

Several factors accelerate stretching:

- Temperature changes: Heat softens nylon, making ties more likely to stretch.

- Constant load: Heavy bundles pull on ties, increasing strain.

- Moisture absorption: Nylon absorbs water, altering its mechanical properties.

- UV exposure: Sunlight weakens the tie’s structure, reducing resistance.

- Poor installation: Over-tightening damages material, making stretch more likely.

Understanding these factors highlights why not all ties perform equally in every setting.

Learn more: Removing Melted Ties Without Damaging Cables.

The Consequences of Stretch

When cable ties stretch, systems lose their stability.

- Cable movement: Loose bundles shift, creating wear points.

- Safety risks: Falling or moving cables cause hazards in workplaces.

- Electrical failure: Movement exposes insulation, increasing the risk of shorts.

- Downtime: Loose wiring in telecom or data centers causes outages.

- Extra costs: Maintenance teams spend more time replacing failed ties.

Stretching reduces both safety and efficiency. In critical industries, these consequences can be severe.

How Long Do Ties Last?

The lifespan of a cable tie depends on its material, environment, and application. Standard nylon ties may last years indoors but degrade in months outdoors.

Weather-resistant, UV-stabilized, or stainless steel ties resist stretching far longer. Proper installation and environmental planning extend tie lifespan significantly.

Prevention Tips for Cable Tie Stretch

1. Choose the Right Material

Selecting the right tie for the environment is the most important step.

- Indoor projects: Standard nylon ties may suffice.

- Outdoor installations: Use UV-stabilized nylon.

- High heat environments: Heat-stabilized nylon or stainless steel is best.

- Heavy loads: Stainless steel ties resist stretch completely.

Learn more: When Ties Crack in Cold: Getting Reliable Performance.

2. Use Proper Installation Tools

Hand tightening often leads to inconsistent tension. Over-tightening damages ties, while under-tightening reduces effectiveness. Tensioning tools ensure proper, consistent application.

3. Avoid Overloading

Every tie has a rated tensile strength. Exceeding this rating increases the chance of stretch or breakage. Select ties rated for loads heavier than expected.

4. Reduce Environmental Stress

UV rays, moisture, and chemicals accelerate stretching. Using protective conduits, coatings, or selecting resistant materials minimizes these risks.

5. Inspect Regularly

Routine inspections help identify stretched or sagging ties before they fail. Replace ties showing signs of slack, discoloration, or brittleness.

6. Use Wider Ties

Wider ties distribute stress across more surface area, reducing the likelihood of stretching under heavy loads.

Industry Applications

Data Centers

In data centers, cable ties manage sensitive fiber optic cables. Stretching creates slack, risking tangling and airflow obstruction. Using UV-stabilized or releasable ties ensures better long-term performance.

Automotive

Vehicles face constant vibration and heat. Stretched ties loosen wire harnesses, creating noise and wear. Heat-stabilized nylon or stainless steel ties are essential in these conditions.

Telecommunications

Outdoor telecom towers endure sun, rain, and wind. Stretching reduces reliability in signal wiring. UV-rated ties keep bundles secure.

Construction

On construction sites, heavy bundles and harsh conditions test ties daily. Stainless steel or weather-resistant ties ensure cables stay in place long-term.

Aerospace

Aircraft wiring cannot afford stretch or failure. High-performance fluoropolymer or stainless steel ties maintain integrity in extreme conditions.

Tools That Support Prevention

The right tools reduce installation errors and extend cable tie life.

- Tensioning tools: Apply consistent force and trim excess cleanly.

- Flush cutters: Prevent sharp edges that weaken ties.

- Removal tools: Allow safe adjustments without over-stressing cables.

Professional tools make a measurable difference in preventing stretch.

Product Review: Heavy Duty Cable Ties

Cable Ties Unlimited offers Heavy Duty Cable Ties designed for demanding applications. With tensile strengths up to 120 pounds, these ties resist stretching under load.

Made from durable nylon 6/6, they are available in natural and UV-resistant black. Their wide width distributes stress, reducing tension loss over time. Suitable for both indoor and outdoor use, they perform across a temperature range of -40 °F to 185 °F.

For professionals managing heavy bundles or outdoor installations, these ties provide the durability and reliability needed to prevent stretch and maintain performance.

Mistakes to Avoid

- Using indoor ties outdoors: They stretch quickly under UV stress.

- Over-tightening: Weakens material and accelerates stretch.

- Ignoring load ratings: Stretch occurs faster when ratings are exceeded.

- Skipping inspections: Small stretches worsen into complete failures.

The Cost of Stretch Failures

A single stretched tie may not seem costly, but cumulative failures add up. Loose wiring increases labor costs, downtime, and safety risks. Investing in quality ties prevents these expenses.

In industries where uptime is critical, prevention is not optional—it is essential.

Future Innovations

Manufacturers are exploring new materials that resist stress relaxation better than nylon. Advanced polymers may soon combine flexibility with long-term strength.

Smart ties are another innovation. These ties could alert technicians when tension drops, signaling early signs of stretch.

Sustainability will also play a role. Recyclable and biodegradable materials designed for outdoor strength will reduce environmental impact.

Wrapping Up

Cable tie stretch is a common but preventable issue. By choosing the right material, installing correctly, and inspecting regularly, professionals keep systems secure and reliable.

Products like Heavy Duty Cable Ties from Cable Ties Unlimited provide the strength needed to resist stretch in demanding environments.

For industries where reliability and safety matter, preventing cable tie stretch ensures long-term success. Small choices at installation make the difference between performance and costly failure.

For more insights and tips on cable ties and other related products, explore cabletiesunlimited.com, get a quick and free quote, and follow us on our social media communities on Facebook and Instagram!

Cable ties stretch over time, creating risks and costs. Learn prevention tips and see why heavy duty cable ties ensure long-term reliability.

Color-coded cable ties are more than aesthetic. They help technicians identify cables, separate functions, and streamline maintenance. Outdoors, however, color fading is a real challenge. Exposure to sunlight, weather, and pollution causes ties to lose their original color, making organization harder.

When color fades, efficiency suffers. Technicians waste time tracing cables that no longer match their intended code. In industries like telecom, energy, or construction, this small problem creates large costs. Understanding why fading occurs and how to prevent it ensures long-term reliability for outdoor projects.

This guide explains the science behind fading, the risks it introduces, and the solutions professionals use to maintain clarity outdoors.

Why Color Fading Happens

Color fading is primarily caused by ultraviolet (UV) radiation. UV rays break down chemical bonds in dyes and plastics, causing them to lose vibrancy. Over time, bright colors like red, yellow, or blue fade into dull shades or near-black.

Other factors accelerate fading:

- Heat exposure: High temperatures make dyes more vulnerable to UV damage.

- Moisture: Rain or humidity washes out pigments.

- Pollution: Chemicals in the air react with plastics, dulling colors.

- Low-quality ties: Cheap dyes and poor manufacturing leave ties more prone to fading.

Outdoor installations that face direct sunlight year-round, like solar farms or highway projects, are especially affected.

The Consequences of Color Fading

Color fading is more than cosmetic. It impacts organization, safety, and maintenance efficiency.

- Loss of identification: Color-coded systems fail when faded ties no longer match documentation.

- Increased labor costs: Technicians spend more time checking cables manually.

- Higher error risk: Mistakenly cutting or adjusting the wrong cable leads to downtime.

- Customer impact: In data centers or telecom, a single misidentified cable can disrupt hundreds of users.

In industries where every minute counts, faded ties undermine productivity and safety.

Materials That Resist Fading

UV-Stabilized Nylon

Black UV-stabilized ties are most common outdoors. The black pigment itself absorbs UV rays, reducing plastic breakdown. While effective, they lack color variety, making them less useful for coded systems.

Weather-Resistant Nylon

Weather-resistant ties include additives that protect both the nylon and the dye. They last longer outdoors than standard ties and maintain color more effectively.

Fluoropolymer Ties

High-performance plastics like ETFE or PVDF resist UV damage better than nylon. Their chemical stability keeps both the tie and its color intact longer. These are used in aerospace, marine, and chemical industries.

Coated Stainless Steel Ties

Stainless steel ties with colored epoxy or PVC coatings offer both strength and fade resistance. The coating protects from UV while providing vibrant colors for identification.

Preventing Color Fading

Preventing fading starts with product choice and smart installation practices.

Select the Right Tie

For long-term outdoor projects, always use UV-stabilized or weather-resistant ties. Colored nylon ties designed only for indoor use will fade quickly outdoors.

Use Protective Coatings

Some ties come with protective coatings that extend color life. For critical color coding, coated stainless steel ties are the most reliable option.

Minimize Sun Exposure

Whenever possible, install cables and ties in shaded areas or inside protective conduits. Reducing direct sunlight slows fading.

Replace Proactively

Even the best ties eventually fade. Regular inspections and scheduled replacements ensure systems remain easy to manage.

Industry Examples

Telecommunications

Telecom towers rely on color coding to separate signal, power, and ground cables. Faded ties risk confusion during upgrades or repairs. UV-resistant or coated ties ensure long-term visibility.

Solar Farms

Solar installations require miles of cable management outdoors. Faded ties make maintenance harder. Weather-resistant or stainless steel coated ties keep identification clear over years of sun exposure.

Transportation

Highway lighting and signaling systems use color coding extensively. Faded ties increase risks during maintenance. Using outdoor-rated ties ensures compliance and safety.

Marine Applications

On docks and boats, ties face both UV and salt spray. Fluoropolymer or coated stainless steel ties provide reliable color stability.

Tools That Help

While product choice is the biggest factor, tools help maintain long-term organization.

- Labeling systems: Printed or engraved labels supplement color coding.

- Protective conduits: Reduce exposure by covering cable bundles.

- Cable markers: Use alongside ties to reinforce identification.

Combining these tools with UV-resistant ties creates redundancy, ensuring systems remain clear even if colors fade.

Cost Versus Value

UV-stabilized or coated ties cost more than standard nylon. However, the savings in labor, reduced downtime, and improved safety outweigh the expense. A single misidentified cable in a data center can cost thousands in downtime. Investing in fade-resistant ties pays off quickly.

Product Review: UV Black Cable Ties

Cable Ties Unlimited offers UV Black Cable Ties designed for outdoor reliability. Made from durable nylon 6/6 with UV stabilizers, these ties resist fading and embrittlement in sunlight.

With tensile strengths ranging from 18 to 175 pounds, they cover applications from small bundles to heavy-duty projects. Their black pigmentation ensures superior UV resistance, making them ideal for telecom, solar, and construction industries.

Available in multiple lengths and quantities, these ties provide flexibility for both short-term projects and long-term outdoor installations. For professionals who need dependable outdoor performance, they are a reliable solution.

Mistakes to Avoid

- Using indoor ties outdoors: Colored nylon ties without UV stabilization fade quickly.

- Overlooking coatings: Unprotected metal ties risk both rust and fading.

- Skipping inspections: Faded ties must be replaced before causing confusion.

- Ignoring redundancy: Relying solely on color without labels increases risks.

Future of Outdoor Color Ties

Manufacturers continue to improve dyes and plastics for better UV resistance. Future innovations may include smart pigments that resist fading even in extreme sunlight.

Sustainable solutions are also on the horizon. Recyclable or biodegradable ties with UV resistance could reduce environmental impact while maintaining performance.

Digital tracking may play a role as well. Color fading issues may be offset by QR-coded or RFID-enabled ties, adding another layer of identification beyond color.

Wrapping Up

Color fading on outdoor cable ties is a persistent challenge, but it can be managed. Understanding UV exposure, selecting the right materials, and using protective solutions ensures long-term clarity and reliability.

Products like UV Black Cable Ties from Cable Ties Unlimited prove the value of UV-resistant designs. With enhanced durability and fade resistance, they keep systems organized and reliable even under harsh sunlight.

For industries across the United States that depend on outdoor organization, preventing color fading is more than maintenance—it is essential for safety, efficiency, and success.

For more insights and tips on cable ties and other related products, explore cabletiesunlimited.com, get a quick and free quote, and follow us on our social media communities on Facebook and Instagram!

Outdoor cable ties fade in sunlight, creating confusion and risks. Learn how UV cable ties prevent fading and keep systems organized outdoors.

Cable ties are built for strength, organization, and reliability. They hold cables together, secure wiring to surfaces, and manage bundles in almost every industry. But extreme heat introduces a challenge. In manufacturing plants, data centers, and even vehicles, cable ties can melt. When this happens, removing them safely becomes critical.

Melted ties fuse to cables, making removal tricky. Pulling or cutting too aggressively risks damaging insulation. Damaged insulation can lead to electrical shorts, performance issues, or safety hazards. Removing melted ties without damaging cables requires patience, the right tools, and smart techniques.

This guide explains why cable ties melt, the risks they pose, and step-by-step methods to remove them. It also highlights products designed to withstand high temperatures so future projects avoid this problem altogether.

Why Cable Ties Melt

Most cable ties are made from nylon 6/6. While durable and flexible, nylon softens under heat. Standard ties usually handle temperatures up to 185 °F. In environments where heat exceeds this threshold, ties may warp, soften, or melt.

Common causes of melted ties include:

- High ambient heat: Manufacturing plants, foundries, or server rooms generate constant heat.

- Direct contact with hot components: Engine parts or industrial equipment can radiate extreme temperatures.

- Electrical overloads: Overheating wires can transfer heat to nearby ties.

- Fires or sparks: Accidental exposure to flames melts ties instantly.

When ties melt, they bond tightly to cable insulation, creating a sticky, hardened mess.

Risks of Melted Ties

Removing a melted tie the wrong way can cause serious problems.

- Cable damage: Cutting too close can nick insulation.

- System failure: Damaged insulation may cause short circuits.

- Safety hazards: Exposed wires risk fires or shocks.

- Downtime: Replacing damaged cables costs time and money.

These risks make careful removal essential, especially in critical industries like aerospace, telecom, or healthcare.

Step-by-Step: Removing Melted Ties

1. Assess the Damage

Before starting, examine the cable bundle. Determine how many ties melted and how much material fused to the cables. In some cases, replacing the entire section of cable is safer than removal.

2. Prepare Tools

Gather safe tools designed for precision. Recommended tools include:

- Flush cutters with narrow tips

- Cable tie removal tools

- Plastic scrapers or spudgers

- Isopropyl alcohol and wipes

- Heat gun or hair dryer for controlled softening

Avoid knives or box cutters. Their sharp edges increase the risk of insulation cuts.

3. Soften the Tie (If Necessary)

If the tie hardened in place, apply gentle heat with a heat gun or hair dryer. This softens the material slightly, making it easier to scrape or lift away. Be careful not to overheat the cable itself.

4. Scrape Carefully

Use a plastic scraper or spudger to separate melted plastic from the cable. Work slowly, lifting small sections at a time. Avoid metal tools unless working on armored cables.

5. Cut Residue in Layers

For thick melted sections, use flush cutters to trim away excess material. Work in layers rather than attempting one large cut. This reduces pressure on the cable insulation.

6. Clean the Surface

After most of the tie is removed, use isopropyl alcohol on a cloth or wipe to dissolve remaining residue. Alcohol evaporates quickly, leaving no moisture behind. For sticky or burnt sections, multiple passes may be required.

7. Inspect Cables

Once the tie is removed, inspect the insulation. Look for nicks, abrasions, or signs of heat damage. If insulation appears compromised, replace the cable before reuse.

Tools That Make a Difference

Flush Cutters

Flush cutters leave smooth edges and allow precise cutting around delicate insulation. They are essential when ties are fused tightly to cables.

Removal Tools

Specialized removal tools slip under the tie head or residue, protecting cables while cutting. They are useful in tight bundles where flush cutters cannot reach.

Heat Guns

Controlled heat helps soften hardened plastic without damaging cables. Low settings should always be used, with constant motion to avoid hotspots.

Alcohol Wipes

Alcohol cleans adhesive-like residue left behind by partially melted ties. They are safe for most insulation types and prevent future dirt buildup.

Preventing Melted Ties

The best way to deal with melted ties is to prevent them. Choosing the right tie material for the environment makes all the difference.

Heat-Stabilized Nylon

Heat-stabilized nylon ties resist higher temperatures, often up to 250 °F. They are suitable for hot industrial environments where standard nylon fails.

Fluoropolymer Ties

Materials like ETFE and PVDF handle both high heat and chemicals. These ties are ideal for aerospace or chemical processing facilities.

Stainless Steel Ties

For extreme heat, stainless steel cable ties are unmatched. They withstand temperatures far beyond nylon’s limits, making them reliable in foundries, automotive plants, and refineries.

Installation Best Practices

- Keep ties away from heat sources when possible.

- Use spacing or mounts to reduce direct heat exposure.

- Avoid over-tightening, which increases stress under heat.

Industry Applications

Data Centers

In server rooms, overheating cables can transfer heat to ties. Using heat-stabilized or plenum-rated ties reduces melting risks.

Automotive

Under-hood wiring faces constant heat from engines. Cold-rated nylon may crack, while heat-resistant nylon or stainless steel performs better.

Manufacturing

Plants with ovens, furnaces, or welders expose ties to high heat daily. Only stainless steel or high-performance plastics can survive here.

Aerospace

Aircraft wiring experiences both extreme heat and cold. High-performance ties certified for aerospace use are essential.

Product Review: Stainless Steel Cable Ties

Cable Ties Unlimited provides Stainless Steel Cable Ties built for extreme environments. Resistant to temperatures that melt nylon, these ties maintain strength in both heat and cold.

Made from corrosion-resistant stainless steel, they provide long-term durability in industries like oil and gas, aerospace, and automotive. Their ball-locking mechanism ensures quick, secure installation. Rounded edges protect cable insulation, preventing abrasion.

For projects where melted ties have been a recurring problem, stainless steel versions eliminate the risk. They deliver the reliable performance that standard nylon cannot match under heat stress.

Mistakes to Avoid

- Using the wrong tool: Knives risk cutting insulation.

- Overheating cables: Heat guns must be kept moving to prevent damage.

- Ignoring inspection: Even if the tie is removed, cables may already be damaged.

- Reusing compromised cables: Replacing damaged wires is safer than repairing.

Long-Term Value of Heat-Resistant Ties

Heat-resistant ties may cost more upfront, but they save time and prevent failures. Every melted tie removed is a reminder that standard nylon is not always the right choice. Stainless steel or high-performance plastics ensure cables remain secure and protected.

In critical industries, downtime from cable damage costs far more than investing in better materials from the start.

Future of Cable Tie Materials

Research continues into advanced polymers that resist both heat and environmental stress. Hybrid materials may soon offer the flexibility of nylon with the resilience of stainless steel.

Self-monitoring ties that indicate when exposed to excess heat may also emerge. These smart designs would alert technicians before melting occurs.

Sustainable materials are another frontier. Heat-resistant ties that are recyclable or biodegradable would combine performance with environmental responsibility.

Conclusion

Removing melted cable ties without damaging cables requires patience, precision, and the right tools. Scraping, controlled heat, and alcohol cleaning help eliminate residue while protecting insulation. But prevention is always better than repair.

Choosing heat-stabilized nylon, fluoropolymers, or stainless steel ties ensures cables remain secure even in extreme heat. Products like Stainless Steel Cable Ties from Cable Ties Unlimited eliminate the risk of melted ties entirely.

For U.S. industries where safety and reliability matter, investing in heat-resistant ties is the smart choice. With proper materials and safe removal techniques, cables stay protected no matter how hot the environment gets.

For more insights and tips on cable ties and other related products, explore cabletiesunlimited.com, get a quick and free quote, and follow us on our social media communities on Facebook and Instagram!

Melted cable ties are frustrating and risky. Learn how to remove them safely and why stainless steel cable ties are the best long-term solution.

Outdoor installations put cable ties to the test. They face constant sun, rain, snow, and wind. Over time, the environment breaks down weak materials. One problem that frustrates many installers is rust stains. These stains can appear on siding, vehicles, or equipment when the wrong type of tie is used outdoors.

Rust stains are not just cosmetic. They can indicate corrosion, which weakens the tie and compromises security. In critical outdoor projects like telecom towers, solar farms, or transportation infrastructure, a single failed tie can lead to larger failures. Avoiding rust requires choosing the right materials, applying correct techniques, and maintaining installations.

This guide explores why rust stains occur, how to prevent them, and which cable ties are designed for outdoor reliability.

Why Rust Stains Appear

Rust forms when metals oxidize in the presence of moisture and oxygen. Some cable ties use metal locking mechanisms. If these are not stainless steel or corrosion-resistant alloys, they can rust. As water carries particles across surfaces, it leaves stains.

Plastic ties without proper UV resistance also degrade over time. As they weaken, embedded metal parts may corrode and stain nearby surfaces. Even stainless steel ties can leave stains if contaminants collect on them, though this is less common.

Risks of Rust Outdoors

Rust stains cause more than unsightly marks. They signal deeper problems.

- Structural weakness: Corrosion weakens the locking mechanism.

- Cable damage: Rust particles can scratch or cut insulation.

- Surface damage: Stains on painted siding or vehicles can be costly to clean.

- System failure: Failed ties risk loose cables, safety hazards, and downtime.

In industries where uptime matters, such as telecommunications or energy, these risks add significant costs.

Common Causes of Rust Stains on Cable Ties

- Poor-quality materials: Low-grade metals rust quickly outdoors.

- Lack of UV stabilization: Nylon ties without UV additives degrade, exposing components.

- Harsh environments: Coastal areas with salt spray accelerate corrosion.

- Improper installation: Over-tightening damages protective coatings, leading to rust.

- Contamination: Dirt or metal particles settling on ties cause surface staining.

Materials That Resist Rust

Weather-Resistant Nylon

Weather-resistant ties include additives that protect against moisture and temperature extremes. They last longer outdoors than standard nylon but may still struggle in salt-heavy air.

Stainless Steel Cable Ties

Stainless steel ties are the gold standard for outdoor durability. Made from grades like 304 or 316 stainless steel, they resist corrosion even in marine environments. Their smooth design also prevents staining when properly installed.

Coated Stainless Steel

Some stainless steel ties come with epoxy or PVC coatings. These prevent direct metal contact with surfaces, reducing staining risks. They also add a layer of insulation, protecting cables from abrasion.

Preventing Rust Stains

Select the Right Tie

Always match tie material to the environment. Nylon ties are fine for short-term outdoor use, but stainless steel is best for long-term projects.

Use Coated Options

If working near visible surfaces like siding or painted equipment, coated stainless steel ties prevent metal-on-surface contact, avoiding stains.

Install Carefully

Over-tightening stainless steel ties can scratch protective coatings. Use tensioning tools for consistent, safe installation.

Perform Maintenance

Regularly inspect ties in outdoor environments. Replace ties that show wear, discoloration, or surface buildup before stains form.

Clean Surrounding Surfaces

Rust can spread from outside contaminants. Keep equipment and siding clean to minimize staining.

Industry Examples

Telecommunications

Cell towers exposed to wind and rain rely on stainless steel ties. Without them, rust stains and corroded locks risk communication outages.

Solar Energy

Solar farms often use coated stainless steel ties. These prevent stains on panels and support structures while resisting UV and heat.

Automotive and Transportation

Vehicles and roadside equipment face constant moisture and salt. Stainless steel ties resist corrosion in harsh winter road conditions.

Marine Applications

Boats and coastal equipment demand 316 stainless steel ties. Their superior corrosion resistance ensures reliability near saltwater.

Tools That Help

Using the right tools ensures ties are installed correctly and stay secure.

- Stainless steel tension tools: Apply consistent tension without damaging coatings.

- Flush cutters: Provide smooth edges when cutting nylon ties, reducing weak points.

- Protective gloves: Prevent contamination of ties during installation.

Product Review: Stainless Steel Cable Ties

Cable Ties Unlimited offers Stainless Steel Cable Ties designed to resist rust and corrosion in outdoor environments. Crafted from high-grade stainless steel, they maintain tensile strength even in harsh conditions.

Available in uncoated or coated options, these ties provide flexibility for different applications. The ball-locking mechanism ensures secure fastening, while rounded edges protect cable insulation. For long-term outdoor projects, these ties deliver unmatched reliability and stain prevention.

From telecom towers to marine equipment, stainless steel cable ties are the best defense against rust stains. Their durability makes them a cost-effective solution for U.S. industries where outdoor reliability is essential.

Mistakes to Avoid

- Using indoor ties outdoors: Standard nylon ties fail quickly in sunlight and moisture.

- Mixing metals: Combining different metals in contact accelerates corrosion.

- Neglecting inspections: Ignoring maintenance leads to unexpected failures.

- Overlooking coatings: Bare steel against painted surfaces increases stain risk.

Cost Versus Value

Stainless steel ties cost more upfront, but they outlast nylon many times over. Their resistance to rust and staining prevents costly repairs, replacements, and downtime. For critical outdoor projects, their value far exceeds the initial investment.

Future of Outdoor Cable Ties

Material innovation is reducing rust risks even further. Manufacturers are developing advanced coatings that combine strength with non-marking surfaces. Sustainable options, such as recyclable weather-resistant polymers, may one day replace nylon for short-term outdoor use.

Smart monitoring solutions are also on the horizon. Ties embedded with sensors could alert technicians when corrosion begins, allowing preventive maintenance before stains and failures appear.

Wrapping Up

Rust stains from outdoor cable ties are more than an eyesore. They signal corrosion that threatens system reliability. Choosing the right materials, applying careful installation techniques, and performing maintenance ensures long-term performance.

Products like Stainless Steel Cable Ties from Cable Ties Unlimited deliver rust-free, reliable performance. Available in coated and uncoated designs, they protect both cables and surrounding surfaces.

For industries that depend on outdoor reliability, avoiding rust stains begins with the right cable ties. With stainless steel and proper installation, outdoor projects remain secure, clean, and dependable.

For more insights and tips on cable ties and other related products, explore cabletiesunlimited.com, get a quick and free quote, and follow us on our social media communities on Facebook and Instagram!

Rust stains weaken outdoor cable ties and damage surfaces. Learn how stainless steel cable ties prevent corrosion and provide reliable outdoor performance.

Cable ties are meant to make work easier, not harder. They secure cables quickly and keep wiring neat. But when a tie snags and refuses to unlock, frustration begins. Technicians may waste valuable time struggling to release it, or worse, damage cables in the process.

Snagged ties are more common than many think. They appear in everything from small office setups to large-scale construction projects. Learning how to fix these stubborn ties safely prevents delays and protects wiring. This guide covers why ties snag, how to free them, and which tools make the job simple.

Why Cable Ties Snag

Most cable ties use a self-locking mechanism. A small pawl inside the head grips the ridges of the tie, preventing backward movement. When this mechanism jams, the tie feels stuck.

Snagging often occurs due to:

- Over-tightening during installation

- Dirt or debris in the lock mechanism

- Use of low-quality ties with rough mold edges

- Cold weather stiffening the plastic

- Old or brittle ties losing flexibility

Understanding why ties snag helps prevent the problem in future installations.

Risks of Forcing a Tie

When a tie does not unlock, the natural instinct is to pull harder. But forcing a tie can damage nearby cables. It can also create sharp edges if the tie breaks suddenly. In high-stakes environments like data centers or aircraft wiring, this risk is unacceptable.

Forcing a snagged tie may also waste time. Minutes spent struggling with a small plastic strip add up on large projects. Technicians need safer, faster solutions.

Methods for Fixing Snagged Ties

Use a Release Tool

Some cable ties are designed as releasable. They feature a small tab that, when pressed, disengages the pawl. Specialized release tools can help press the tab even in tight spaces. These tools slide under the tie head and push gently, unlocking the tie without damage.

Precision Cutting

If the tie refuses to release, cutting may be the best option. Flush cutters or cable tie removal tools cut ties close to the head, leaving smooth edges. Unlike scissors or knives, these tools prevent nicks and scratches to nearby cables.

Apply Gentle Heat

For ties stuck due to cold brittleness, warming the tie may restore enough flexibility to disengage the lock. A hair dryer or heat gun set to low can soften the tie slightly. Care must be taken not to overheat or damage cables.

Lubrication

In dusty or dirty environments, a small drop of silicone spray or isopropyl alcohol may loosen a jammed lock. This works best when dirt is the cause of snagging. Always clean cables afterward to prevent residue.

Preventing Snagged Ties in the Future

The best fix is prevention. Careful installation and product selection reduce snagging issues.

- Avoid over-tightening: Leave slight movement space for cables.

- Use releasable ties: These are designed for easy unlocking.

- Choose quality products: Cheap ties have rough molding that increases snagging.

- Work at proper temperatures: Store ties indoors before use in cold conditions.

Technicians who follow these steps reduce the number of snagged ties dramatically.

Industry Scenarios

Data Centers

In data centers, cable ties must often be removed during upgrades or troubleshooting. A snagged tie wastes time and risks expensive fiber optic cables. Releasable ties or proper cutters are essential here.

Automotive

Automotive technicians frequently adjust wiring harnesses. Snagged ties in cramped engine bays are difficult to reach. Releasable ties and long-nose flush cutters simplify this work.

Construction

On job sites, workers deal with dust, dirt, and cold weather. These conditions increase snagging. Using high-quality weather-resistant ties minimizes issues.

Aerospace

Aircraft wiring cannot afford damage from a forced tie removal. Releasable designs and certified removal tools ensure safe handling.

Product Review: Releasable Cable Ties

Cable Ties Unlimited offers Releasable Cable Ties that solve the snagging problem. These ties include a built-in release tab, allowing technicians to unlock and reuse them easily. Made from durable nylon 6/6, they provide strength while offering flexibility during adjustments.

Available in multiple lengths and tensile strengths, releasable ties are suitable for projects ranging from office setups to industrial installations. Their design reduces waste by allowing reuse, and their smooth release prevents damage to sensitive cables.

For technicians tired of wrestling with snagged ties, these products are a practical solution. They save time, protect wiring, and support sustainable practices by reducing single-use waste.

Learn more: Polyamide Releasable Cable Ties: The Ultimate Solution for Temporary Fastening.

Tools That Help

Specialized tools make fixing snagged ties easier.

- Flush cutters: Provide clean cuts with no sharp edges.

- Removal tools: Protect cables by sliding under the head before cutting.

- Tensioning tools with built-in cutters: Allow consistent installation and smooth removal.

Keeping these tools in a kit ensures technicians are ready for snagged ties anytime.

The Cost of Snagged Ties

While a single tie may seem insignificant, the costs add up. Time wasted on a stuck tie delays projects. Cable damage increases maintenance costs. In industries like aerospace, one mistake can even risk safety.

Investing in releasable ties and proper tools may cost more upfront, but the long-term savings in time and reduced risk are substantial.

Future Trends

Manufacturers are developing new designs to reduce snagging. Smooth-lock systems, reusable designs, and even “smart” ties with indicators may reduce future problems. Materials that resist cold embrittlement and dirt buildup are also being tested.

These innovations will further reduce frustration for technicians while increasing safety and efficiency.

Wrapping Up

Snagged cable ties slow work, frustrate technicians, and risk damaging cables. Fixing them safely requires release tools, cutters, or sometimes heat and lubrication. Prevention through careful installation and quality product selection is the most effective long-term solution.

Products like Releasable Cable Ties from Cable Ties Unlimited make unlocking simple. With built-in release tabs, they prevent snagging issues altogether while supporting reuse and sustainability.

For U.S. industries where efficiency and safety matter, solving the problem of snagged ties is a small step with a big impact. The right products and tools ensure smoother work and better results.

For more insights and tips on cable ties and other related products, explore cabletiesunlimited.com, get a quick and free quote, and follow us on our social media communities on Facebook and Instagram!

Snagged cable ties waste time and risk damage. Discover how to fix them with safe tools and why releasable cable ties are the best prevention.

Cold weather is brutal on materials. Plastics stiffen, metals contract, and adhesives lose their grip. Cable ties are no exception. In freezing conditions, standard nylon ties can crack, snap, or fail, leaving cables exposed. For industries that operate in the cold, this is more than an inconvenience—it is a risk.

When ties break in low temperatures, critical systems can lose stability. Imagine fiber optic cables in a telecom tower or wiring in an aircraft exposed to icy conditions. A single failure can cause costly downtime or safety hazards. Reliable performance requires choosing the right tie for the environment.

This guide explains why ties crack in cold weather, what materials hold up better, and how to prevent failures. It also reviews a product designed to withstand extreme cold, ensuring secure bundling even in the harshest U.S. winters.

Why Standard Nylon Struggles in the Cold

Most cable ties are made from nylon 6/6. This material is strong, affordable, and widely used. However, nylon has a weakness—it absorbs moisture. When temperatures drop below freezing, absorbed water crystallizes, making nylon brittle.

At room temperature, a nylon tie bends easily. In subzero weather, the same tie may snap when tightened. The colder the environment, the greater the risk. Below -4 °F, standard nylon ties often cannot maintain their rated tensile strength.

Real-World Impact of Cracked Ties

A cracked tie is not just a minor nuisance. It can have real consequences:

- Telecommunications: Exposed wires on towers lose stability, leading to service interruptions.

- Automotive: Wire harnesses in vehicles fail, causing electrical issues or safety risks.

- Aerospace: Cracked ties in aircraft wiring jeopardize system reliability.

- Construction: Failing ties in outdoor installations delay projects and increase labor costs.

Every failure adds expense and risk. That is why choosing cold-resistant ties is critical.

Materials Designed for Cold

Heat-Stabilized Nylon

Heat-stabilized nylon is often used in hot environments, but it also provides slightly improved performance in cold compared to standard nylon. It is still not the best option for subzero applications.

UV-Stabilized Nylon

UV ties are designed for outdoor use in sunlight. While stronger against UV rays, they do not significantly improve cold-weather performance.

Weather-Resistant Nylon

Some nylon blends are modified for cold weather. These resist embrittlement longer, holding strength down to around -40 °F. They are better suited for outdoor work in U.S. winters.

Fluoropolymers (ETFE, PVDF)

High-performance plastics such as ETFE (ethylene tetrafluoroethylene) resist extreme temperatures. They perform well below freezing while also withstanding high heat and chemicals. These ties are more expensive but deliver unmatched durability.

Stainless Steel

For the most extreme cold, stainless steel cable ties are the top choice. Steel does not embrittle in freezing conditions. These ties maintain full strength whether exposed to arctic wind or subzero temperatures. They also resist UV rays, chemicals, and fire.

Testing Cold-Weather Performance

Cold-rated ties undergo rigorous testing. ASTM and UL standards often specify temperature ranges for safe use. A reliable cold-weather tie should:

- Maintain tensile strength at -40 °F or lower

- Resist cracking during installation

- Retain flexibility during service life

- Pass flammability standards for safety

Testing ensures ties can survive both installation and long-term exposure in cold climates.

Installation Tips in Cold Weather

Even the best tie can fail if installed poorly in freezing temperatures. Following best practices prevents problems.

- Warm ties before use: Store ties in a heated environment before taking them outside.

- Use proper tension tools: Over-tightening in cold makes brittle ties more likely to crack.

- Avoid sharp bends: Cold ties are less flexible. Bend slowly to reduce stress.

- Choose larger sizes: Thicker ties distribute stress better and resist snapping.

Technicians working in freezing conditions must adjust their methods as much as their materials.

Applications That Demand Cold-Resistant Ties

Telecommunications

Cell towers in northern states like Minnesota or Maine endure brutal winters. Reliable ties ensure cables remain secure despite wind, ice, and extreme cold.

Energy Sector

Oil and gas facilities in Alaska face subzero conditions for months. Cold-resistant ties keep wiring secure in processing plants and pipelines.

Automotive and Trucking

Vehicles in northern climates face freezing starts, road salt, and snow. Cold-rated ties keep harnesses intact through repeated freeze-thaw cycles.

Aerospace

Aircraft wiring faces freezing temperatures at altitude. Cold-resistant ties ensure system safety during every flight.

Construction

Outdoor construction projects continue year-round in many U.S. regions. Using cold-rated ties prevents costly delays caused by broken fasteners.

Cost Versus Value

Cold-resistant cable ties cost more than standard nylon ties. However, their value comes from preventing failures. A snapped tie may seem minor, but the labor to replace it in freezing weather is costly. Delays, downtime, and rework add even more expense.

Investing in cold-rated ties saves money in the long term. They reduce maintenance, increase safety, and ensure projects stay on schedule.

Learn more: How to Differentiate Between Cable Ties for Indoor and Outdoor Uses.

Product Review: Stainless Steel Cable Ties

For extreme cold, Stainless Steel Cable Ties from Cable Ties Unlimited provide unmatched reliability. Crafted from durable stainless steel, these ties maintain full tensile strength in freezing conditions. Unlike nylon, they do not embrittle when exposed to cold or moisture.

These ties also resist chemicals, UV rays, and fire, making them suitable for the harshest environments. With a ball-locking mechanism, installation is quick and secure. Rounded edges prevent cable damage, ensuring both safety and performance.

Available in multiple lengths and tensile strengths, stainless steel cable ties meet the needs of industries from telecommunications to aerospace. For professionals working in U.S. winters or arctic environments, they are the most dependable choice for cold-weather performance.

Avoiding Common Mistakes

One mistake is assuming UV-resistant or heat-stabilized ties work in freezing conditions. These ties are designed for sunlight or heat, not extreme cold. Another mistake is using standard nylon outdoors in winter. Even if they seem strong indoors, they often snap outside.

Failing to warm ties before use is another issue. Cold ties straight from unheated storage are brittle and prone to cracking. Keeping them indoors until needed reduces this risk.

Future of Cold-Resistant Cable Ties

Material science continues to evolve. Researchers are developing nylon blends with greater flexibility at subzero temperatures. These new plastics may close the gap between affordable nylon and premium fluoropolymers or steel.

Smart ties may also play a role. Embedded sensors could alert technicians if a tie is nearing failure due to temperature stress. This would allow proactive maintenance before ties snap.

Sustainability will also influence design. Cold-resistant ties made from recyclable or biodegradable materials may emerge, combining durability with environmental responsibility.

Wrapping Up

Cold weather is unforgiving. Standard nylon ties crack and fail, risking safety and increasing costs. Reliable performance in freezing environments requires the right material, proper installation, and smart planning.

Weather-resistant nylon and fluoropolymers provide improved performance, but stainless steel remains the gold standard for extreme cold. Products like Stainless Steel Cable Ties ensure cables stay secure in U.S. winters, even at -40 °F or below.

For industries that cannot afford downtime, investing in cold-rated cable ties is essential. With the right products and practices, ties will hold firm no matter how low the temperature drops.